In 2011, Air Works (via his subsidiary company A2Wind) developed an aerodynamic and performances feasibility study for the Korean company KM for the design of Stall Regulated Wind Blade Family for 750 kW for length variable between 14.2m and 15.5m for wind class III with an aerodynamic tip brake system.

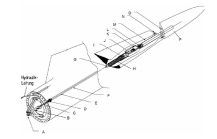

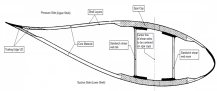

- The blade is built as a self-supporting structure comprising of two skin-halves mounted round the main spar.

- Two U-beams goes from the Root end to tip.

- Bushings with internal thread are embedded in the root section, and so forming the attachment to the hub. This root-to-hub-mounting-principle has been extensively

- Shells, spars and root section are made of fibre-glass reinforced polyester, where the main strength properties have been achieved by using continuous fibres (Unidirectional Rowings). The bushings are made of chrome alloy steel. All metal parts for the aerodynamic blade tip brake are made of stainless steel and carbon fiber/epoxy.

- The aerodynamic tip brake consists of the outer 2090 mm of the blade, mounted on a carbon/epoxy shaft.

- The profile chosen DU and NACA 63-XXX series has proven highly productive and shows little sensitivity to dirt. Also the stalling properties are fine.