AEROSPACE TECHNOLGIES FOR TURBINE’S DEVELOPMENT

Since year 2010, AIRWORKS is developing technologies to support Wind Power turbine manufacturers in the segment of large rotor blades.

SERVICE RANGE

- Contractor for complete rotor design

- Contractor for Research & Development projects

- Aerodynamic design of rotor blades

- Structural blade design

- Mould design

- Sizing and Certification of rotor blades according to GL (IEC 64100), DNV

- Design of systems & components (Nacelle, Tower, Hub)

- Turbine load calculations

- Performance optimization on existing turbines

- Implementation of composite materials

- Manufacturing support

BENEFITS

- Know-How and strategies protection

- Networking with main sector’s specialists (ex-ENERCON, MBB,..) and leading companies

- 10 years experience in Lightweight Design for Space and Aeronautics

- CFRP structures optimization capability (already performed for the most advanced aerospatial projects)

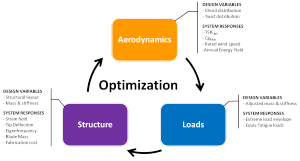

PRE DESIGN

Design Tools

- Aerodynamics: WARP

- Loads: Focus 6

- Math. simulation: Hyperworks

- Aeroelastic Optimization: Proprietary Software

DETAILED DESIGN

- Rotorblade loft

- Structural layout

- Loads

- Design objective

- Design constraints

- Design responses

![]()

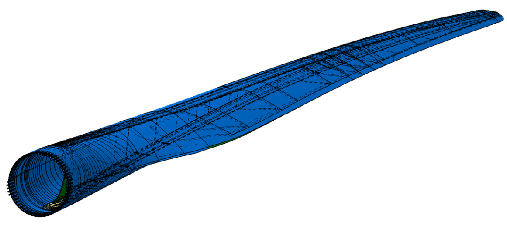

SIZING

![]()

- Laminate plan

- Structural drawings

- Bill of materials

- Design reports

- Test plan

Blade Projects: From Scratch to Certification through Manufacturing:

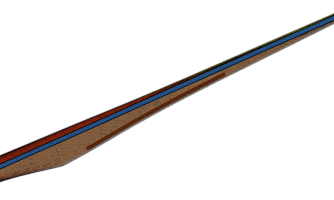

DONGTAI (XEMC) 45.0m – 1.5MW Blade

In 2011, AirWorks (via his shareholded company A2Wind) developed a 45.0m – 1.5MW glass fiber blade from the scratch book to the manufacturing drawings.

Our team was involved in all the phases of the project (including GL certification and tests) and AirWorks personnel was in charge in all the key roles.

The entire sizing and design was carried out in < 5 months.

Client’s main tasks (weight, performances, stiffness, manufacturing process optimization) were completely fulfilled.

Static, fatigue and dynamic loads were obtained by an internally developed Visual Basic code and the commercial software Focus-6. CatiaV5 was used for 3D and 2D CAD.

Aerodynamic predesign is usually carried out using the proprietary code WARP (in cooperation with Uni Roma3 Eng. Dept.) As soon as the blade aerodynamic layout is sufficiently mature, FEM and Focus 6 modeling starts. From that moment on, a feedback loop is constantly running between structural computations

and Aeroelasticity ones. The loop will close when all the tasks will be fulfilled. In the meanwhile, detailed 3D and 2D design will have started. Some detailed analyses (like root bolts) will be

independently developed via dedicated FE-Models but may affect the entire design process.

AirWorks has faced many hard challenges in its technical history and background. Wind turbine blade design and certification process is without any doubts one of the most open-minded and complete, and for sure one of the ones to be most proud of. The strong integration of many disciplines, along with the usually tight leading times, makes the blades definition extremely critical and, under some aspects, fascinating. No many companies around the world exist, which can perform such a job, in such a way/time, and AirWorks is nowadays definitely one of them. As the call for renewable energies raises, AirWorks keeps investing in R&D projects a big part of its income. Our attention is now focused on optimization processes, to cut delivery times and improve blades performances.